Isikhunda

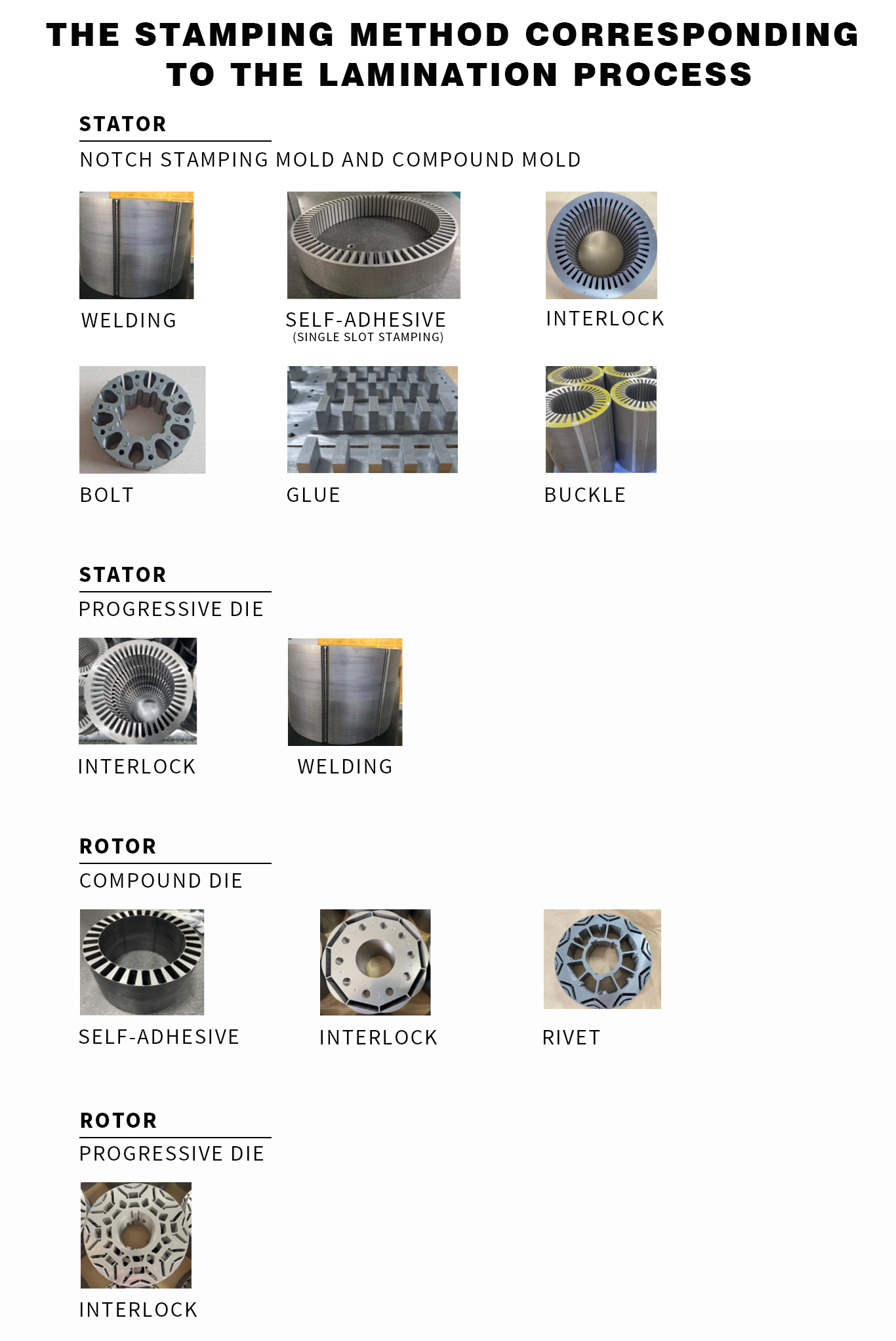

Sine-slot-slot punching, ukubhoboza okuhlanganisiwe, kanye nokubhoboza okuphezulu okuhambisanayo ukuze kuhlangatshezwane nezidingo zezitatimende ezihlukile zezimoto nama-rotors. Cishe 90% yethuIzindlu zokulala zemoto zenziwe ngokwezifiso kusuka kwimidwebo. Ngesikhathi senqubo yokuqamba isikhunta, abaklami bethu abangochwepheshe bazodonsa iziphakamiso ezithile zokwanelisa amakhasimende angcono.

Amasampula enza

Singahlangana nosayizi ohlukile nobuchwepheshe be-motor amasampula wesampula yesampula.

A

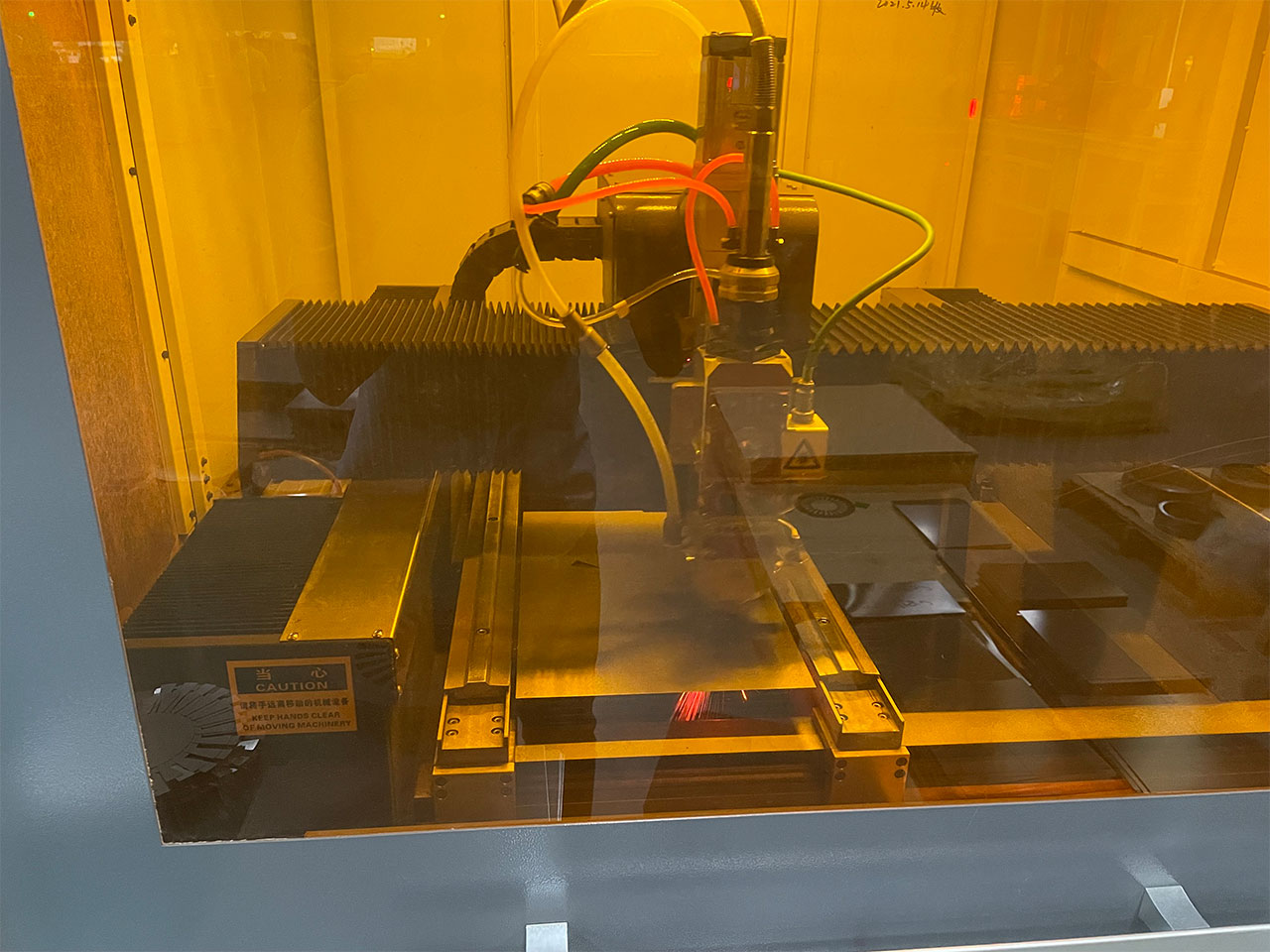

Ukusika kwe-laser

C

Ukusika kwesivinini okuphezulu

B

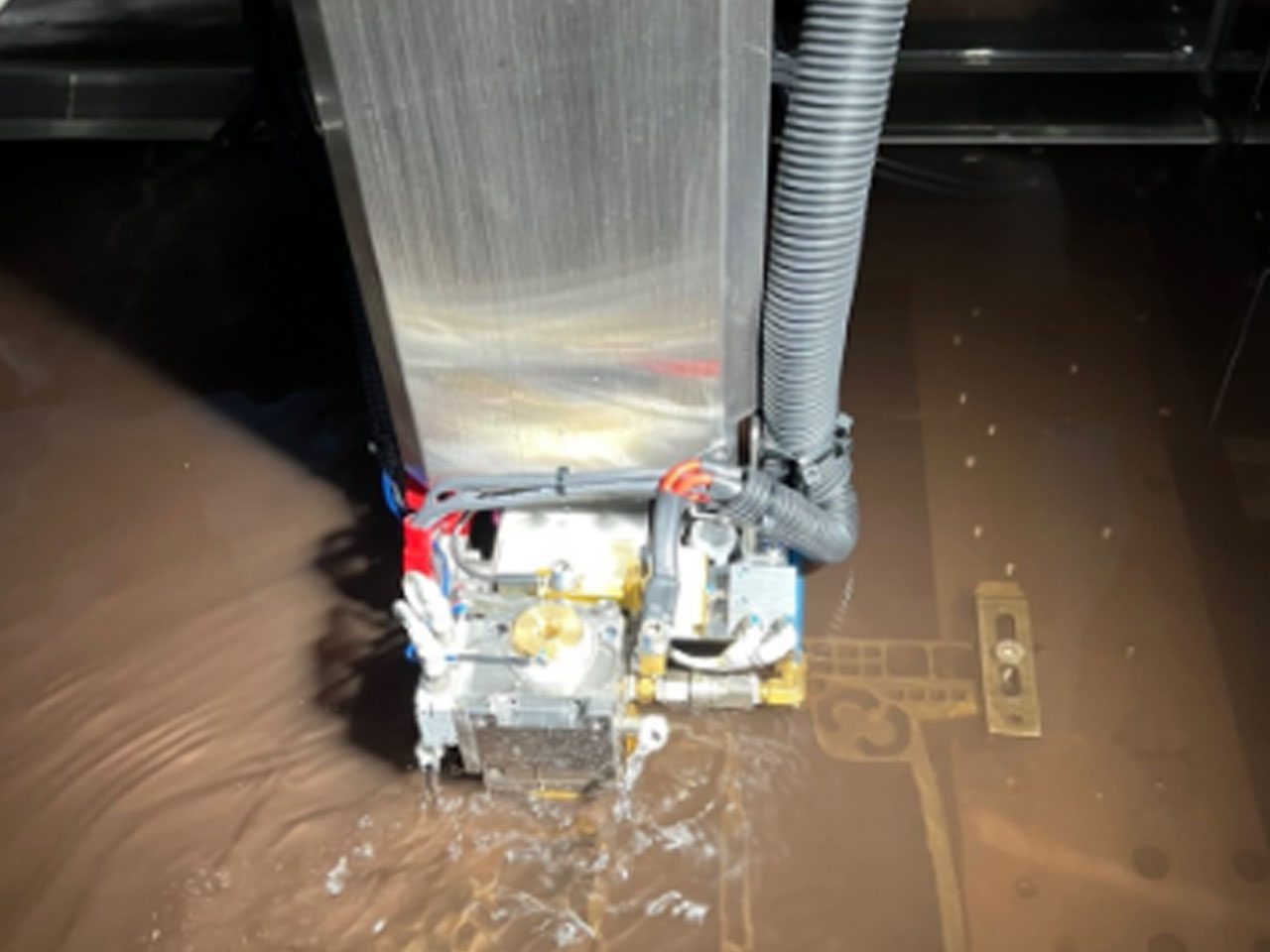

Ukusika kwesivinini esiphakathi

D

Ukusika kwesivinini okuphansi (Singenise umshini we-Seibu Brand kusuka eJapan)

-Dumile

Sinezinhlobo ezahlukene zemishini yokushicilela ukuze sihlangabezane nezidingo zakho ezihlukile zokuthenga.

Isitembu esisodwa se-slot

Izingcindezi: 10t-16t

Ukunqamulwa kwe-compound

Izingcindezi: 40t-550T

-Phambili(Ijubane eliphezuluIsihlehlukene-Dumile

Imishini: 630T, 550T, 315T (Schuler),I-300t (AIDA),I-160t, 120t, 80t (nidec)

Ukuqinisa i-workshop & inzuzo

↓

A.Instrodus the advanced sculer Exced & technology kusuka eJalimanene-AIDA, NIDEC evela eJapan,esivumela thina kuIzindlu zokulala zemotoimboni ehola phambili manje.

B.AchACIWAZUWAZUZWA KOKUGCINWA KWESI-0.1MM Spireness Alicon kanye ne-0.03mm ubukhulu bezinto ezingezona ezingezona ze-alloy.

C.Therle Slot Press ingamisa isitayela Od2000mm Max.

Isitembu esisodwa se-slot

Ithuluzi: Notch stanging die

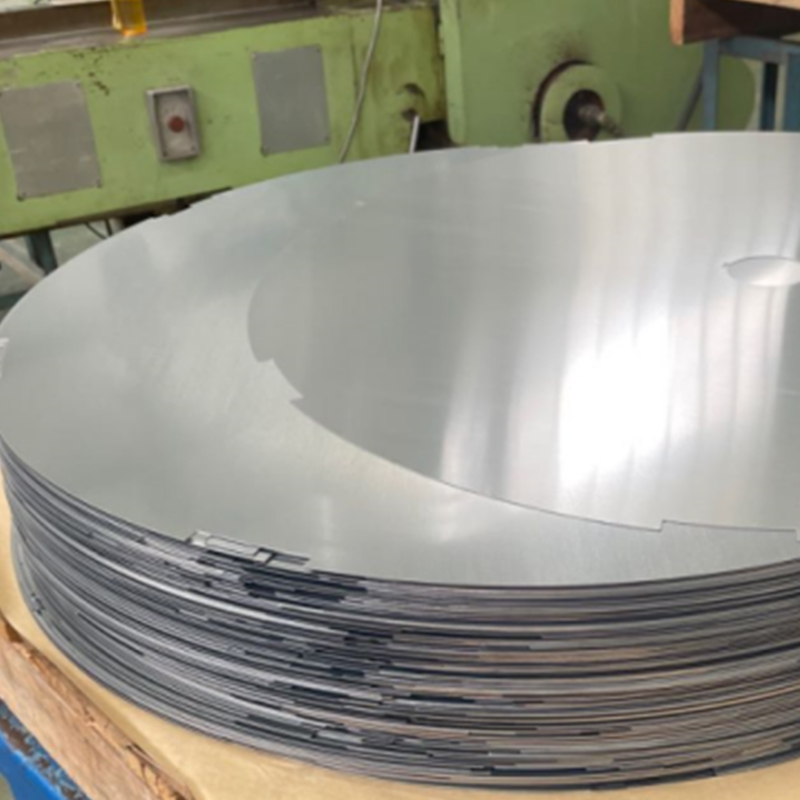

Sika ishidi lensimbi ye-silicon ukuze ufune usayizi, futhi ucezu ngalunye lwazo luzogxivizwa ngakunye ngesimo esidingekayo. Isitembu esisodwa se-slot siyindlela efanelekile ye-stator laminations enobubanzi obukhulu obukhulu nenani elikhulu lamasampula.

Ukunqamulwa kwe-compound

Ithuluzi: I-Compound iyafa

Thenga umucu wensimbi we-silicon ohambelana nosayizi womkhiqizo odingekayo, udlulise impahla kumaphepha wokucindezela isitembu, bese wenza ama-motor laminations, zombili izitebele kanye ne-rotor lamination. Kunezindlela ezimbili zokudla, eyodwa ukusebenzisa i-wafer punched yinye indawo yokuvinjwa kwemoto, engasebenzi, kepha ingagcina izindleko ezibonakalayo; Okunye ukuzondla okuqhubekayo kwemichilo, okusebenzayo kakhulu Ngaphezu kwalokho, inkampani yethu inelungelo lobunikazi ekusebenzeni ngokuzibumba okuhlanganisiwe, okunciphisa kakhulu izindleko zokuqinisekiswa kwezimoto zezimoto ekuqaleni kwesitembu sokuqala se-acturestive die batch.

Ukuthuthuka okuqhubekayo

Ithuluzi: Ukufa Okuqhubekayo

Lolu hlobo lwesikhunta lubizwa nangokuthi isikhunta esinejubane eliphezulu. Ehlukile kubumba obuhlanganisiwe, ingasebenzisa kuphela ububanzi obufanelekile bokondla, ukuqeda ukuncipha nokuzithoba ekubumbeni ngokuqondile ukwakha i-stator ne-rotor tick.

Kunezinhlobo ezimbili zokuzithoba. Eyokuqala iphuzu lokuzindla ngokuzindilinga ngobukhulu obuncane bezimoto zezimoto, ezinezidingo eziphezulu zobuchwepheshe. Izitaki azidingi ukucindezelwa kabili kuthuluzi lokulungiswa.Ilinye iphuzu elixakile lokuzimela, elidinga ingcindezi yesibili yokuqinisekisa ukuqiniseka.

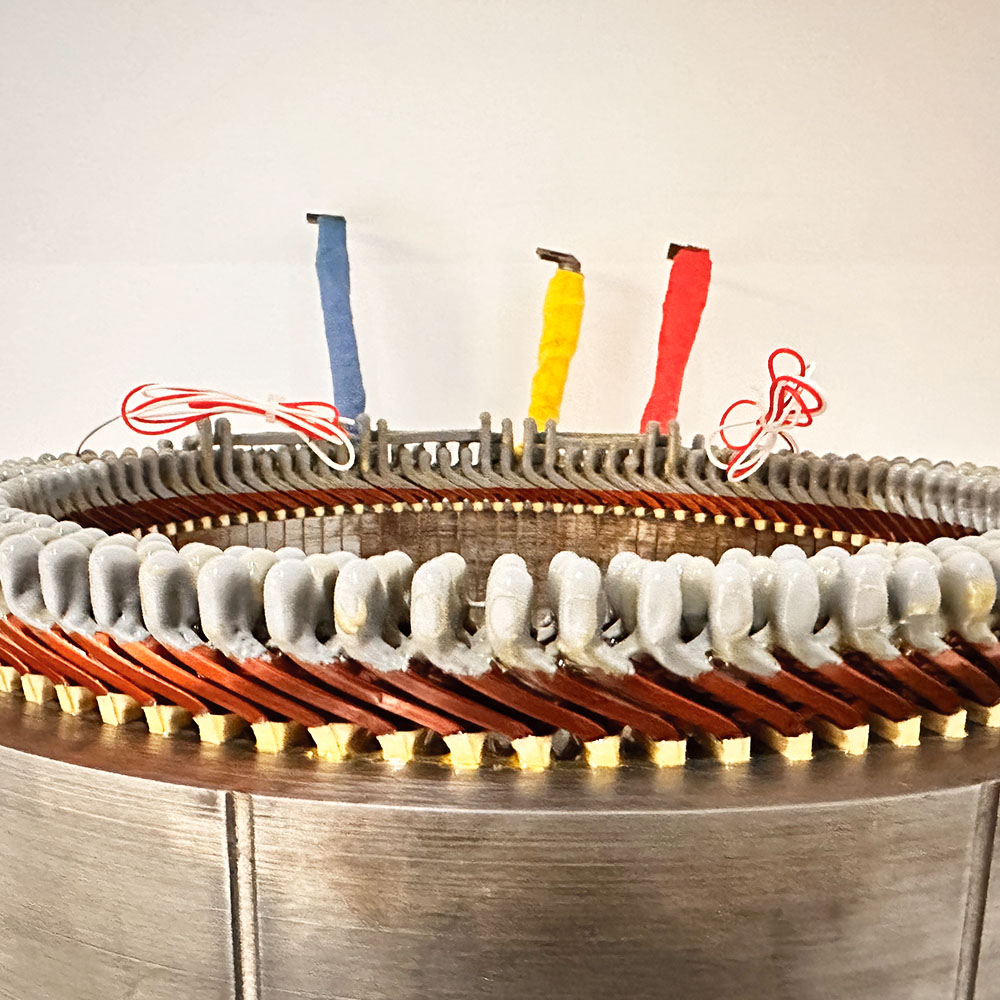

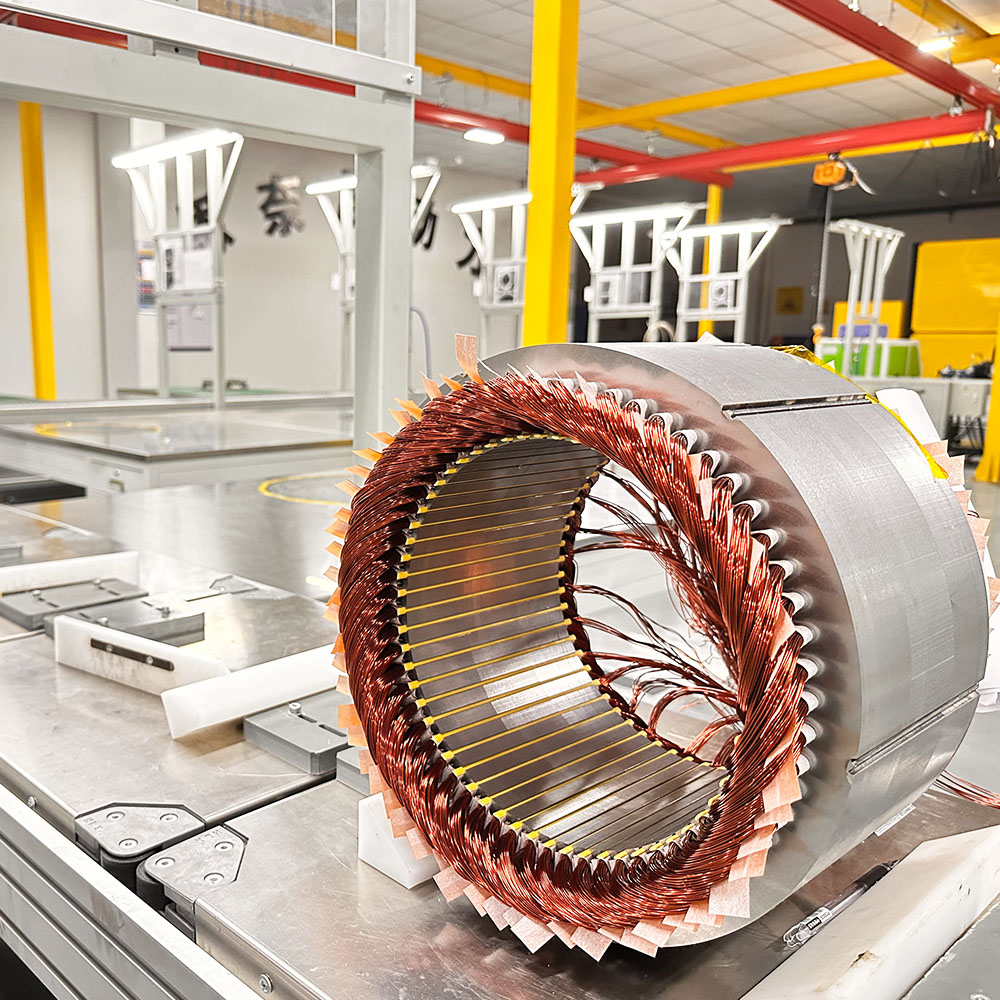

Ukujikeleza komhlangano weStator

Sinikezela ngocingo oluyindilinga kanye ne-PIN i-Winking, zombili izimbambo ezincane esigabeni sesampula kanye namabheji amakhulu esiteji esizayo, 1, ubukhulu be-pin winding i-150-400mm, 2-8 izingqimba 2. Okwamanje umthamo wokukhiqiza umkhiqizo Eziyisisekelo 5-50 isethi / usuku.

Ukucwilisa

Ukuvinjwa kuzofakwa ku-coret nge-rivet, ukuxhumeka, ukuthutha, ukuzinamathela, glue, bolt, i-mberle, njll.

Isivuno

Ukufaka izimbotshana ngokuvamile kusetshenziselwa i-rotor, kukhona ama-rivet ekhanda kanye ne-rivet eyisicaba.

Ukufudumeza

Ukufakwa kwe-welding kusetshenziselwa i-stator laminations, kukhona i-laser welding kanye ne-tig welding.

Hlanganisa ngegilu

Penda glue kuwo wonke ama-motor ally futhi unamathele ndawonye.

Xhuma

Yenza amaphuzu wokuhlangana ngesikhathi sokugxuma, ukugcwala kwemoto kuzofakwa kuma-cores ngokwawo ngala maphuzu. Ukuhlangana kungaba yindilinga noma isiyingi sendilinga. Ukugxila okuqhubekayo yonke inqubo yokusebenzisa i-interlock ukusindisa i-stator ne-rotor tic tatta kanye nesikhathi.

Ukuzinamathela

Material: B35A300-Z / B50A400-Z

Izinto ezibonakalayo zinama-coating ebusweni bawo, zizoncibilika futhi zinamathisele wonke ama-rotor eyodwa nesitaki esihlalisa ndawonye ngesikhathi sokushisa. Ukuzinamathela kuzokwenza imikhiqizo ibushelelezi futhi iqinile.

Umshudo

I-Bolt ngokuvamile isetshenziselwa ama-stator laminations anobubanzi obukhulu obungaphandle.

Okokuzibopha

Ukufakwa kwe-Buckle kusetshenziselwa ukugcwala kwe-stator, kunamabhande aqondile noma ama-skew.

Ukuhlola

Imishini yethu yokuhlola ifaka i-projektha, imitha yokuxhumanisa ezintathu, umhloli we-Iron Force, umhloli we-Iron Work, umhloli wokumelana we-deflection, umhloli wokumelana we-insulation, njll.

Ukuhlola kuhlukaniswe ngohlolo lwendatshana yokuqala, ukuzihlola, ukuhlola okujikelezayo nokuhlolwa kokugcina. Akunandaba noma iyiphi indlela yokunyathela, izingcezu ezimbalwa zokuqala ze-motor Ukubulawa kwezimoto kanye namasethi ambalwa okuqala e-stator nezitaki ze-rotor kudinga ukuthunyelwa egumbini lokuhlola, futhi ukukhiqizwa kwabantu abaningi kungenziwa kuphela ngemuva kokudluliswa kabusha ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi ukuhlolwa sekudlulile ngemuva kokuthi uhlolo ludlulile ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi ukuhlolwa kudlulile ngemuva kokuthi kuphakanyiswe kuphela ngemuva kokudluliswa.

Ukufaka ndawonye

Ngokusho kwezidingo zamakhasimende, izibalo nama-rotors zigcwele amakheji wensimbi, amabhokisi we-plastiki, amabhokisi e-plywood, amabhokisi enziwe ngokhuni, njll.

Lapho i-motor i-motor eam noma i-stator kanye nezitaki ze-stror ziqediwe, sizobahlukanisa nesiponji bese sipakisha sibe ngamacala okungenzi lokhu lokhuni kokulethwa kwamanye amazwe.